Eurping Laboratory Glassware Washer: Dual Pressure & Flow Control, Worry-Free Irregular Bottle Cleaning

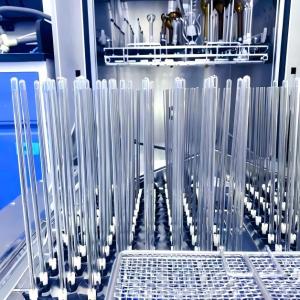

For special vessels like special-shaped bottles and narrow-mouth bottles, manual cleaning struggles to balance dead corner coverage and efficiency. Residual stains can also compromise experimental data. The Tianjin Eurping Q800 Series Bottle washer, with frequency-convertible pressure and flow parameters, easily achieves standardized cleaning of various special-shaped bottles. It meets the needs of multiple scenarios such as universities and pharmaceutical companies.

Influence of Pressure on Cleaning Effect

Pressure is the core driving force for removing stubborn stains.

- Low pressure (0.1-0.2MPa) is suitable for vessels with poor pressure resistance, such as plastic centrifuge tubes, to avoid deformation and damage.

- Medium pressure (0.2-0.5MPa) is the optimal range. It efficiently removes stains like proteins and greases, especially for cleaning dead corners such as the inner walls and mouths of special-shaped bottles.

- High pressure (above 0.5MPa) should be used with caution. It is only suitable for high-pressure resistant vessels like stainless steel measuring tools.

The Eurping Q800 Series is equipped with a pipeline pressure sensor. It displays values in real time, precisely controlling cleaning intensity to perfectly match the optimal cleaning pressure for each vessel.

Influence of Flow Rate on Cleaning Effect

Flow rate determines the circulation efficiency of the cleaning fluid.

- A flow rate below 10L/min may leave residues in the dead corners of special-shaped bottles.

- A flow rate of 10-20L/min enables the cleaning fluid in the chamber to circulate 2-4 times, covering over 90% of the vessel surface.

- A flow rate above 20L/min speeds up the process but tends to lower the temperature of the cleaning fluid.

The circulation pump of the Eurping Q800 Series supports frequency conversion adjustment from 0 to 600L/min. Combined with a modular basket, it firmly fixes special-shaped bottles to ensure uniform coverage of the cleaning fluid.

Operation Suggestions

- For cleaning special-shaped bottles, select a pressure of 0.3-0.4MPa and a flow rate of 15-20L/min. Use an alkaline cleaning agent to enhance stain-removing power.

- Set parameters separately for glass and plastic vessels to avoid damage or incomplete cleaning.

- Calibrate pressure and flow parameters every 3 months. Control the error within 5% to ensure stable cleaning results.