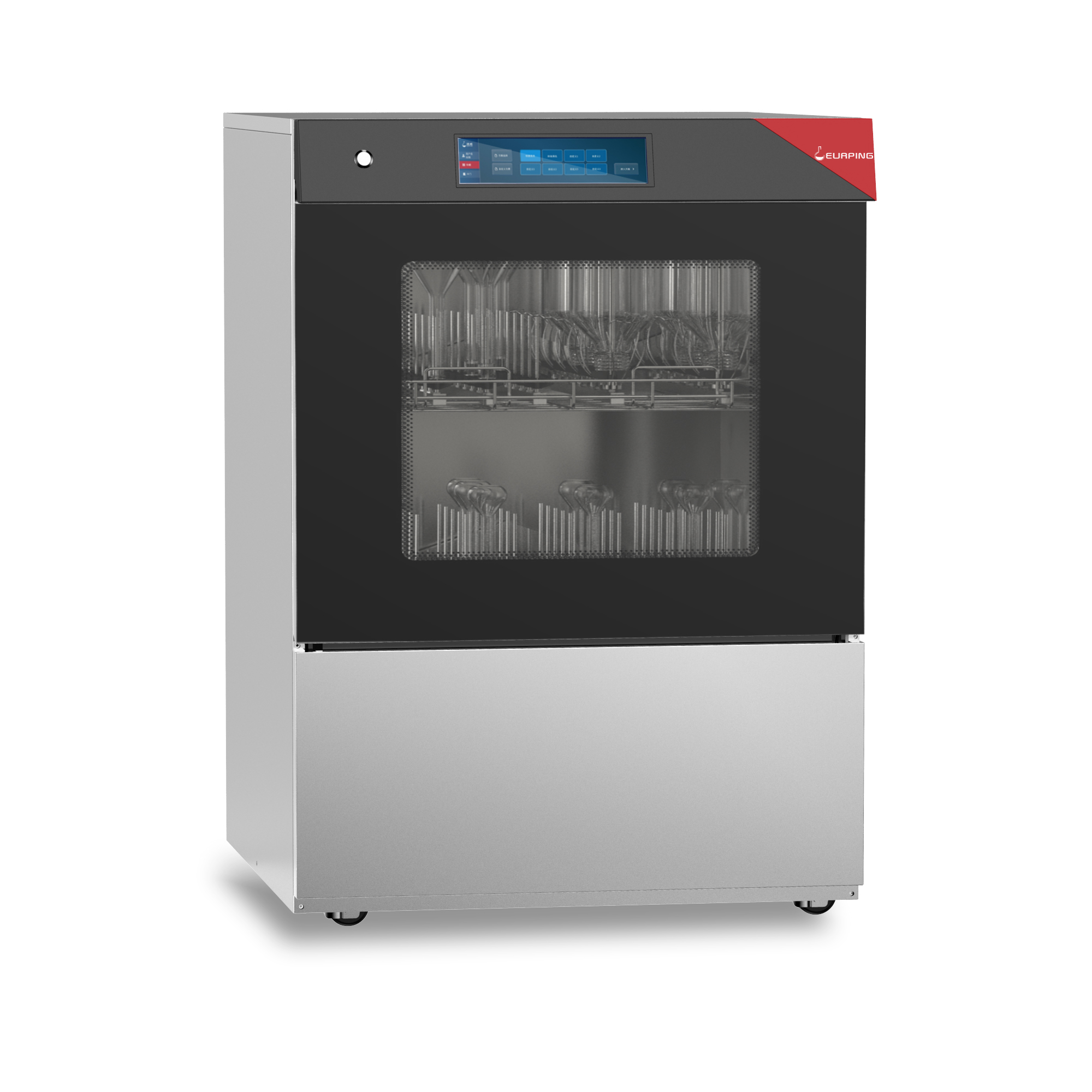

The "Four-Step Cleaning Method" of Eurping Laboratory glassware washers - Black Technology Hides in Every Step

Doing experiments is tough enough – and washing bottles? Even harder! All kinds of residues are not only hard to clean but also time-consuming and labor-intensive. Worse, stains might even mess up your experimental data. But don’t worry! The Eurping Laboratory glassware washers, your "great helper for lab cleaning," has already solved these problems for you. Today, let’s uncover its "cleaning magic" and see why it’s the top choice for so many labs!

The cleaning logic of the Eurping Laboratory glassware washers is actually super simple: it uses a triple combination of "high-pressure water flushing + hot water acceleration + cleaning agent enhancement" to break down stains, and finishes with hot air drying. The whole process is automatic – no need for manual monitoring. Let’s break it down step by step – every step is packed with "black technology"!

High-Pressure Water Spraying: 360° Stain-Free Flushing

The washers’ built-in variable frequency controlled circulation pump generates powerful high-pressure water flow. Through the spray arm and special nozzles, it creates a 360° rotating spray. This mechanical flushing force is just like a high-pressure water gun – it can directly strip off stubborn stains like reagent residues and biofilms from the inner walls of utensils.

Even better, for narrow-lumened laboratory glassware like volumetric flasks and pipettes, it’s designed with an injection drying spray function. The water flow can reach deep inside the utensils directly, totally solving the problem of "can’t reach, can’t clean" with manual washing. Even small 2ml injection vials get spotlessly clean!

Double-Action Combo: Wipe Out Stubborn Stains

Physical flushing alone isn’t enough. The Eurping Laboratory glassware washers come with special high-efficiency cleaning agents, which are accurately dosed into the cleaning chamber via the built-in peristaltic pump. These cleaning agents use chemical or physical emulsification to target different types of stains – like breaking down organic residues or chelating metal ions. At the same time, their neutral formula protects glass scales from corrosion, balancing cleaning power with utensil protection.

Hot Air Drying: Clean and Odor-Free

After cleaning, it’s time for the drying system. It uses a dual HEPA-filtered hot air circulation design. The drying temperature can be freely adjusted from RT (room temperature) to 120℃. The hot air reaches both the inside and outside of the utensils through the injection basket nozzles, drying moisture quickly – and there’s no odor at all during the whole process.

Boost your experiment efficiency – start with "cleaning utensils the right way"!