Four Future Development Directions for Laboratory Cleaning Machines

The market demand for laboratory cleaning machines has been increasing in recent years, and it can be said that they have become standard equipment for large laboratories. Therefore, there are more and more manufacturers producing laboratory cleaning machines. Currently, the competition in the domestic laboratory cleaning machine market is very fierce. What kind of products can stand out in the future development of the laboratory equipment industry? Let's give you a brief analysis below.Firstly, laboratory cleaning machine products should be safe and convenient

The reason for choosing a cleaning machine for glassware is because there are many safety risks associated with manual cleaning. In order to reduce these safety risks during the production process and achieve more convenient and efficient cleaning, a laboratory cleaning machine is chosen. To be equipped with an automatic suction door device, it can help the operator conveniently close the compartment door quietly, effectively preventing vibration damage to various glassware that needs to be washed when closing the door. At the same time, electronic door locks can also effectively control the opening and closing of the main washing compartment door, preventing users from accidentally coming into contact with sewage or being scalded by hot water during use, ensuring greater safety.

Secondly, attention should be paid to supporting facilities

Some cleaning machine manufacturers only focus on the production and sales of cleaning machine hosts, without considering the completeness of supporting equipment, resulting in laboratory cleaning machines not being able to fully perform their intended functions. To this end, it is necessary to match the cleaning basket to greatly expand the functionality of the host, improve the market competitiveness and economy of the equipment, and provide customers who choose cleaning machines with more choices to solve various cleaning problems in the actual production process.

Thirdly, the effect must be good and have a high cleaning rate

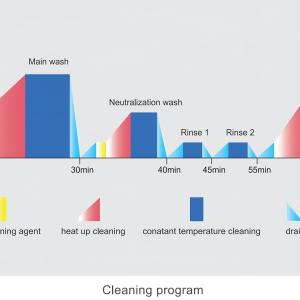

Based on feedback from numerous laboratory professionals, when choosing a fully automatic cleaning machine, the laboratory still values the cleaning rate of the cleaning machine. A cleaning solution that can be provided to meet the cleaning needs of different laboratories. At the same time, choose German imported cleaning agents with better cleaning effects, and then use temperature and the driving force of the cleaning circulation pump to spray the cleaning solution to directly flush the inside and outside of the glassware 360 degrees. Under the action of mechanical and chemical forces, the residual pollutants on the glassware are stripped, emulsified, and decomposed, achieving a satisfactory cleaning rate.

In the era of emphasizing intelligence, we must achieve high automation

According to analysis, future laboratory cleaning machines will follow the trend of industrial automation and develop in these directions:

One is the diversification of mechanical functions. Cleaning machines should be more diversified and refined. Under the same price standard, cleaning machines with multiple switching functions can better meet market demand.

The second is the standardization and modularization of structural design. By fully utilizing the modular design of the original model, modules can be replaced in a short period of time to meet various needs.

The third is intelligent control.

With the increasing demand for experimental results, the selection of pre-treatment and experimental vessels has become increasingly stringent, and laboratory cleaning machines are gradually being accepted by the public. The cleaning process of laboratory cleaning machines is standardized and automated, and the washing quality can be guaranteed. The washing process is safe and reliable, and the washing records can be traced. Choosing a fully automatic laboratory cleaning machine is the correct direction for future laboratories.