Laboratory glassware washer working principle

The working principle of Laboratory glassware washer combines mechanical, chemical and thermodynamic technologies, aiming at efficiently removing residues, dirt and microorganisms inside and outside the containers through automated processes, ensuring that the cleaned containers meet the hygienic standards. The following is a detailed analysis of its core principles and key processes:

一 、The cleaning process and core principles

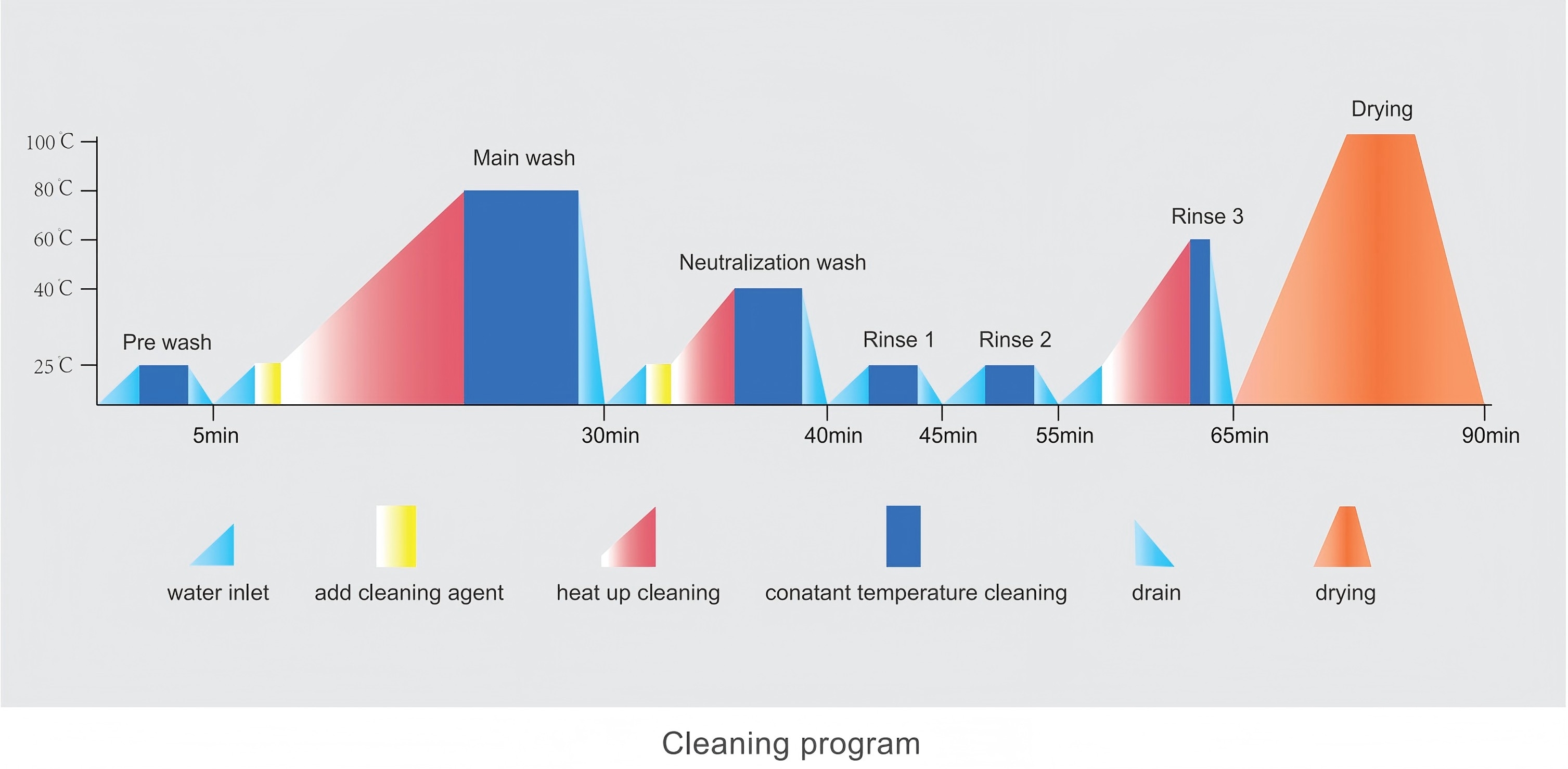

1. Pre-treatment stage

- Pre-rinse: through the high-pressure water or pure water initial flushing container walls, remove large particles of residue and labeling debris. Some models will work with alkaline cleaning agents (such as sodium hydroxide) to soften stubborn stains.

- Temperature control: The pre-wash temperature is usually room temperature or low temperature (e.g., 40-50 ℃) to avoid high temperatures leading to carbonization of organic matter, increasing the difficulty of subsequent cleaning.

2. Main washing stage

- Chemical cleaning: use alkaline or acidic cleaning agents (such as NaOH, chelating agent EDTA) and dirt chemical reaction, decomposition of organic matter, oil and mineral deposits. For example, NaOH removes protein residues through hydrolysis, and chelating agents prevent calcium and magnesium ions from forming scale.

- Mechanical Scrubbing: A high pressure spray system (up to 4-6 bar) with a rotating spray arm scrubs the inside of the vessel 360° to strip away dirt. The spray angle and pressure are dynamically adjusted to the shape of the vessel, ensuring that dead ends are cleaned.

- Temperature synergy: the main washing temperature is usually controlled at 70-90 ℃, high temperature to accelerate the chemical reaction and kill microorganisms (e.g., spores need to be 71 ℃ for more than 2 minutes).

3. Neutralization and rinsing stage

- Neutralization of residues: Acidic solution (e.g. citric acid) to neutralize alkaline detergent residues to prevent corrosion of containers or affect subsequent experiments/production.

- Multi-stage rinsing: Use pure or ultra-pure water for multiple rinses to ensure no chemical residues. Some models use ultrasonic-assisted rinsing to remove tiny particles by cavitation effect.

4. Drying Stage

- Hot air circulation: Rapid evaporation of water by 70-90℃ hot air to avoid secondary pollution of condensate. Part of the equipment is equipped with HEPA filter to ensure clean drying air.

二 、Key components and technology

1. Spraying system

- Composed of high pressure water pump, spray arm and nozzle, the speed of spray arm is matched with the pressure of water flow in real time to avoid foam overflow or uneven cleaning.

2. temperature and chemical control

- Temperature sensor: real-time monitoring of the temperature of the cleaning solution to ensure the efficiency of chemical reaction and sterilization effect.

- Chemical metering system: precise control of the concentration of cleaning agent (e.g. NaOH concentration of 2-5%), through the peristaltic pump automatically add.

3. Automation control

- PLC system: preset a variety of cleaning programs (such as standard wash, fast wash, self-cleaning program), support for user-defined parameters (time, temperature, pressure).

- Fault monitoring: detect spray arm jamming, water level abnormality or motor overload, automatic shutdown to protect the equipment.