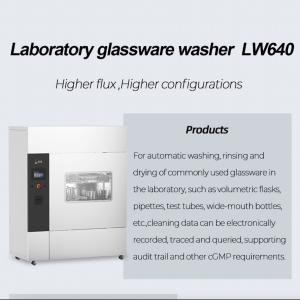

GMP Compliant Tunnel Washer: Revolutionizing Laboratory Compliance Through Continuous Innovation

In the highly regulated landscape of pharmaceutical and biotechnology laboratories, adherence to Good Manufacturing Practices (GMP) is not merely a requirement but a cornerstone of product safety and quality. Traditional batch-style laboratory washers, while functional, often struggle to meet the stringent demands of GMP—particularly in areas like cross-contamination control, reproducibility, and data integrity. Enter the GMP-compliant tunnel washer: a continuous-processing solution that redefines how laboratories approach cleaning validation, operational efficiency, and regulatory compliance. This article explores how tunnel washers are transforming GMP compliance through innovative design, technological integration, and a paradigm shift from batch to continuous workflows.

The GMP Imperative: Why Tunnel washers Matter

GMP regulations mandate that laboratory equipment must minimize the risk of contamination, ensure consistent cleaning performance, and maintain auditable records. Batch washers, which process samples in discrete cycles, introduce inherent risks: manual loading/unloading can lead to human error, variable cycle times compromise reproducibility, and incomplete drainage may leave residues. Tunnel washers address these gaps by employing a continuous, linear workflow where samples move through a series of standardized stations (pre-wash, main wash, rinse, dry) without interruption. This design eliminates batch-to-batch variability and reduces human intervention—key factors in GMP non-compliance.

For example, in a pharmaceutical lab producing sterile injectables, a single contaminated washer cycle could compromise an entire batch. Tunnel washers mitigate this risk by integrating automated loading systems and closed-loop fluid management, ensuring that each sample undergoes identical processing conditions. The result? A reproducible cleaning process that aligns with GMP’s focus on “process consistency.”

Modular Design: The Backbone of GMP Compliance

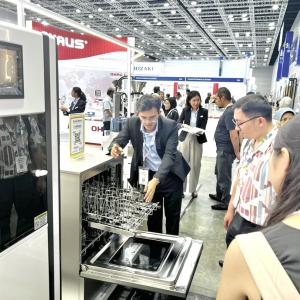

A defining feature of GMP-compliant tunnel washers is their modular architecture. Unlike monolithic batch machines, tunnel washers are built as interconnected modules, each optimized for a specific cleaning step. This modularity serves two critical GMP purposes:

- Cleanability and Validation: Each module (e.g., a stainless steel wash chamber or a HEPA-filtered drying section) is designed for easy disassembly and sanitization. For GMP, this means simplified cleaning validation—laboratories can test and document the effectiveness of each module independently, rather than validating an entire batch process.

- Scalability and Flexibility: Modules can be added or removed to accommodate changing laboratory needs (e.g., increasing sample volume or adding new cleaning agents). This adaptability is invaluable in regulated environments, where processes must evolve without compromising compliance.

Consider a biotech lab transitioning from small-scale research to clinical trials. A modular tunnel washer allows the lab to scale up by adding a larger wash chamber or a more advanced filtration system—without replacing the entire unit. This “future-proofing” aligns with GMP’s emphasis on process robustness.

Technological Integration: AI, IoT, and Data Integrity

Modern GMP-compliant tunnel washers go beyond mechanical design; they leverage AI-driven monitoring and IoT connectivity to enhance compliance. For instance, sensors track parameters like water temperature, detergent concentration, and cycle time in real time, feeding data to a central system that logs every step. This digital trail is indispensable for GMP audits, as it provides irrefutable evidence of process adherence.

AI algorithms further optimize performance by analyzing historical data to predict maintenance needs or adjust cycles for optimal cleaning. In a GMP context, this means proactive issue resolution—preventing downtime that could disrupt validated processes. Additionally, IoT integration enables remote monitoring, allowing lab managers to oversee operations from anywhere, a critical feature for distributed teams or 24/7 facilities.

Data integrity, a GMP cornerstone, is also strengthened through features like electronic batch records (EBRs) and audit trails. Tunnel washers automatically generate these records, eliminating manual documentation errors and ensuring that every cleaning cycle is traceable.

Case Study: A Pharmaceutical Lab’s Success Story

A mid-sized pharmaceutical company recently replaced its batch washer with a GMP-compliant tunnel washer. The results were transformative:

- Compliance: The lab passed a surprise FDA audit with zero findings related to cleaning processes, thanks to the washer’s automated data logging and modular design.

- Efficiency: Sample throughput increased by 40% due to continuous processing, reducing lead times for drug development.

- Cost Savings: Reduced rework (from 5% to 1%) and lower labor costs offset the initial investment within 18 months.

This case highlights how tunnel washers are not just a technical upgrade but a strategic investment in GMP compliance and operational excellence.

Future Trends: Toward Smarter, More Sustainable GMP Compliance

Looking ahead, GMP-compliant tunnel washers will likely integrate sustainable technologies (e.g., water recycling systems) and advanced materials (e.g., antimicrobial coatings) to further reduce contamination risks. Additionally, blockchain-based data storage could enhance auditability, providing an immutable record of every cleaning cycle.

For laboratories, the message is clear: tunnel washers are more than a piece of equipment—they are a pathway to GMP compliance that is efficient, scalable, and future-ready. By embracing continuous innovation, labs can stay ahead of regulatory demands while driving productivity.