Common problems during the use of ultrasonic bottle washing machines

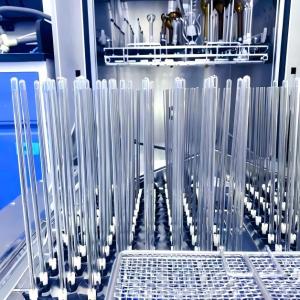

The ultrasonic bottle washing machine utilizes the principle of ultrasonic cavitation. When the bubbles formed by ultrasonic waves suddenly burst, more than 1000 atmospheric pressures are generated, which continuously generate strong micro explosions and shock waves instead of manual labor, causing the dirt on the surface of the cleaned object to be damaged and quickly fall off. As a cleaning instrument, ultrasonic bottle washing machine is a basic equipment in the laboratory. Although it is very ordinary, it has a huge impact and can even affect the entire experimental results. Therefore, mastering the daily operation and troubleshooting of ultrasonic bottle washing machine is a basic skill. Below, we will list the common problems and solutions encountered when using it!1. The problem of bottle overflow on the mesh belt of the ultrasonic bottle washing machine and the risk of bottle tipping when ultrasonic waves enter the twisting dragon area.

Solution: Adjust the overall height of the mesh belt and the speed of the conveyor mesh belt, add F4 strips on both sides of the side plate to reduce friction or increase shrapnel, adjust the gaps and handover heights of various parts, and check whether the ultrasonic frequency is turned on appropriately.

2. The ultrasonic bottle washing machine floats the bottle due to insufficient pressure of injection water, circulating water, compressed air, or insufficient spray water.

Solution: Check if the high-pressure water pump is added to the water supply system, check if the filter element is blocked, replace it with a new filter element as required, check if the direction of the water pump is correct, check if the pipeline is blocked, and clean the water tank filter screen and spray plate.

3. The high water temperature of the ultrasonic bottle washing machine causes the twisting dragon to deform, and the gap between the twisting dragon and the bottom rail of the bottle inlet is too large, resulting in the bottle falling or breaking.

Solution: The injection water used in the ultrasonic bottle washing machine must be controlled at around 500C. If the temperature exceeds this, the heating converter should be increased to control the water temperature, adjust the gap between the twisting dragon and the bottom rail, and replace the twisting dragon with a new one if the twisting dragon is severely deformed.

4. Adjustment of the handover time between the bottle twisting dragon and the lifting block.

Solution: Loosen the M8 inner hexagon screw on the clamping sleeve of the right end coupling of the twisting dragon, rotate the twisting dragon to make the bottle coincide with the lifting block, and then tighten the fixing screw of the clamping sleeve. If there is no obstruction when manually turning the winch to feed the bottle into the feeding block, it indicates that the adjustment has been made properly. Otherwise, further adjustment is needed.

5. The lifting block and sliding bar of the ultrasonic bottle washing machine are deformed due to high water temperature, or the M4 fixing screws are prone to loosening and falling off, resulting in the entire machine being stuck.

Solution: Remove the lifting block and sliding bar and inspect them all. Re glue and tighten the sliding bar, bearing, and M4 fixing screws. If the sliding bar is deformed, it needs to be replaced. If the bearing is damaged, it needs to be replaced with a new imported stainless steel bearing. More importantly, it is important to control the water temperature.

The above are five common problems and corresponding solutions encountered during the use of ultrasonic bottle washing machines, hoping to be helpful to everyone!